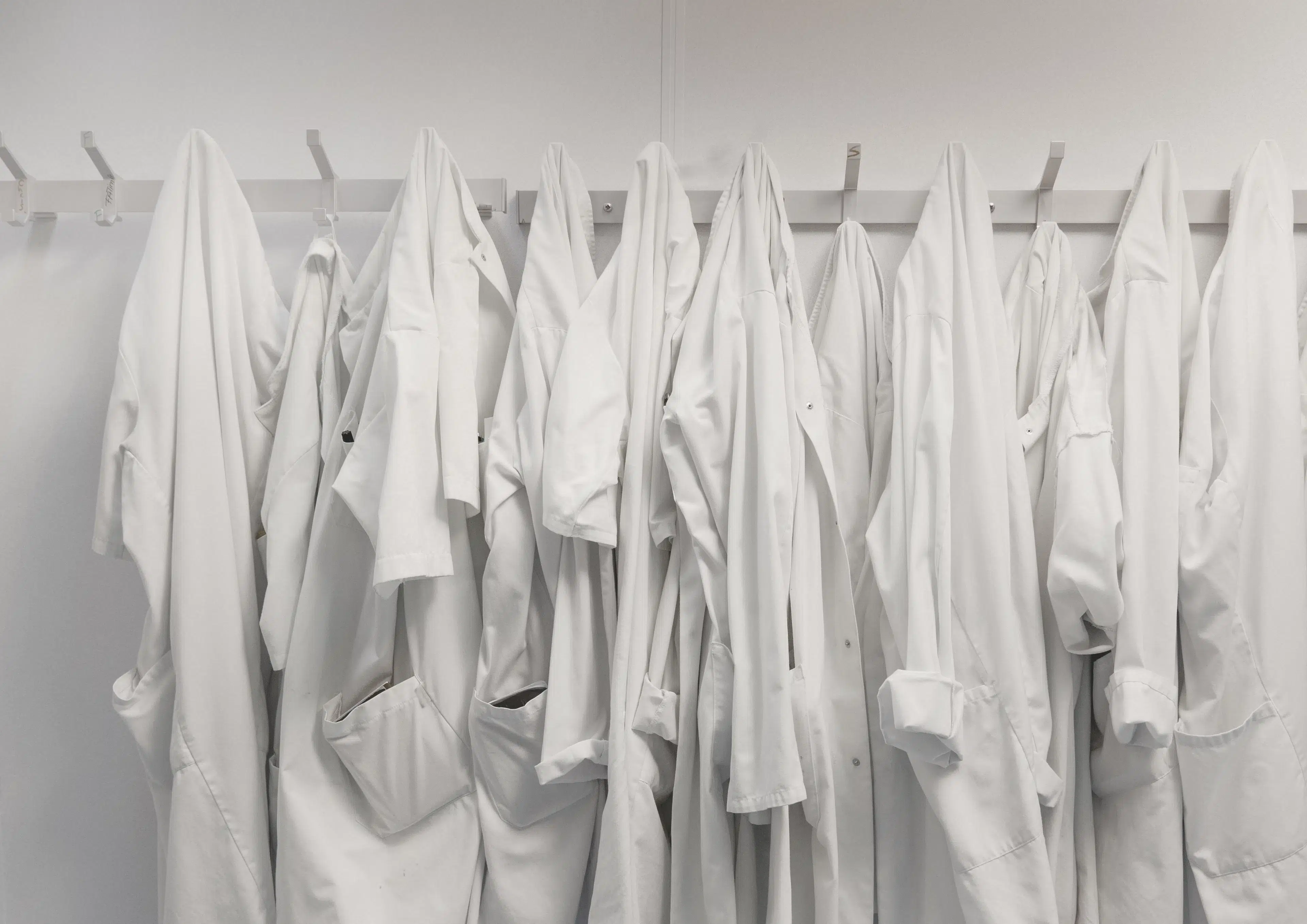

In food production environments, color is more than a design choice – it is a hygiene tool. The color of workwear plays a practical role in supporting HACCP compliance, helping to prevent cross-contamination, and ensuring that employees are easily identifiable according to their tasks or zones.

At Kentaur, we offer a range of colors in our HACCP-certified collection – not just for style, but for function, safety, and visual control.

The role of color in HACCP-compliant workwear

Under HACCP guidelines, one of the key principles is controlling cross-contamination. Using color-coded workwear helps support this by making it easier to:

-

Differentiate between hygiene zones (e.g. low-, medium-, and high-risk areas)

-

Identify staff roles (e.g. raw food handling vs. packaging)

-

Separate shifts, departments, or production lines

-

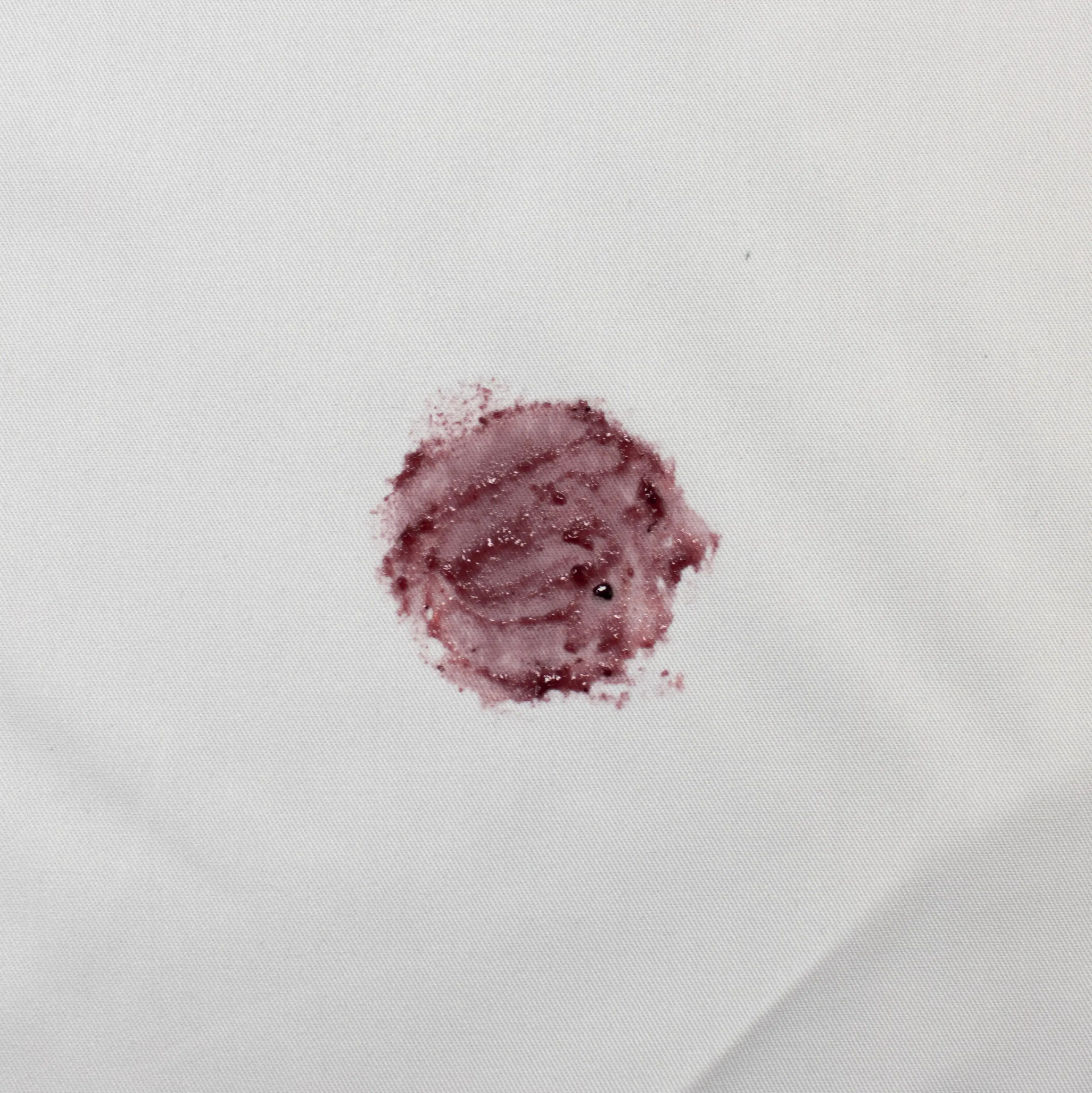

Detect visible contamination on lighter-colored garments in high-risk zones

Supporting zone separation through color

Many companies implement their own color-coding systems to align with internal hygiene protocols. For example:

-

White or light colors are often used in high-risk areas, where visible cleanliness is critical. Light colors make it easier to detect stains or contaminants, helping to reduce the risk of cross-contamination.

-

Darker colors may be used in low- or medium-risk zones, or for staff not in direct contact with unpackaged food.

The most important consideration is that any potential stains or contamination that may occur – especially in risk class 2 or 3 environments – should be easily visible. Choosing the right color supports this by making contamination easier to identify and respond to, helping to maintain hygiene standards throughout production.